The intelligent sodium hypochlorite generator uses the electrochemical principle to prepare sodium hypochlorite solution by electrolysis of salt water on site. The equipment has stable performance, simple operation, safety and reliability, and long service life. It is an ideal sterilization and disinfection product in the water treatment industry.

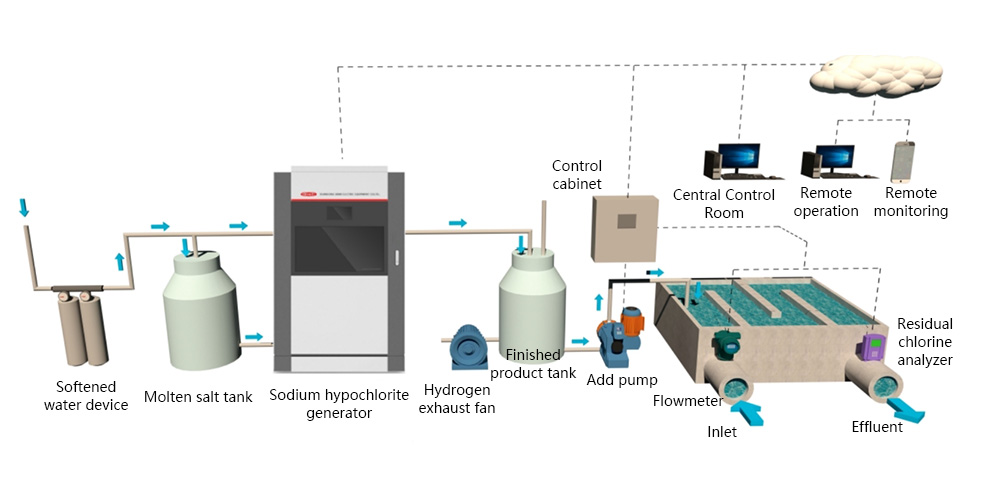

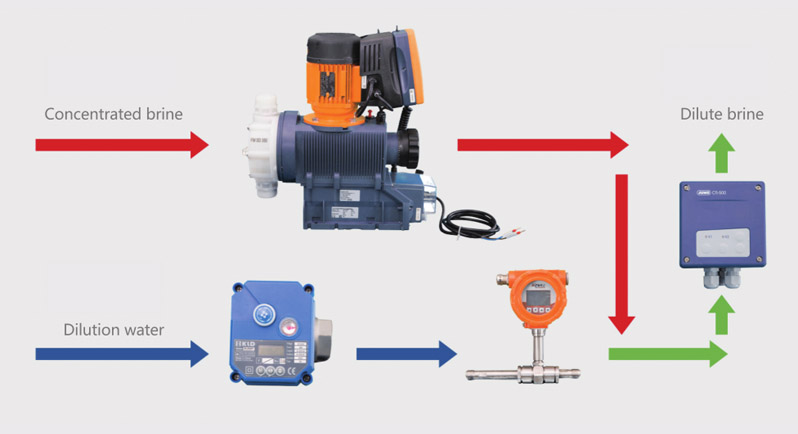

The softened water is controlled and measured by the electric valve and flowmeter. The saturated brine is accurately controlled by the metering pump and dissolved into dilute brine in the pipe mixer. The data of brine is monitored by the concentration meter in real-time. The data is used to control metering pump by feedback to ensure the stable concentration of dilute brine.

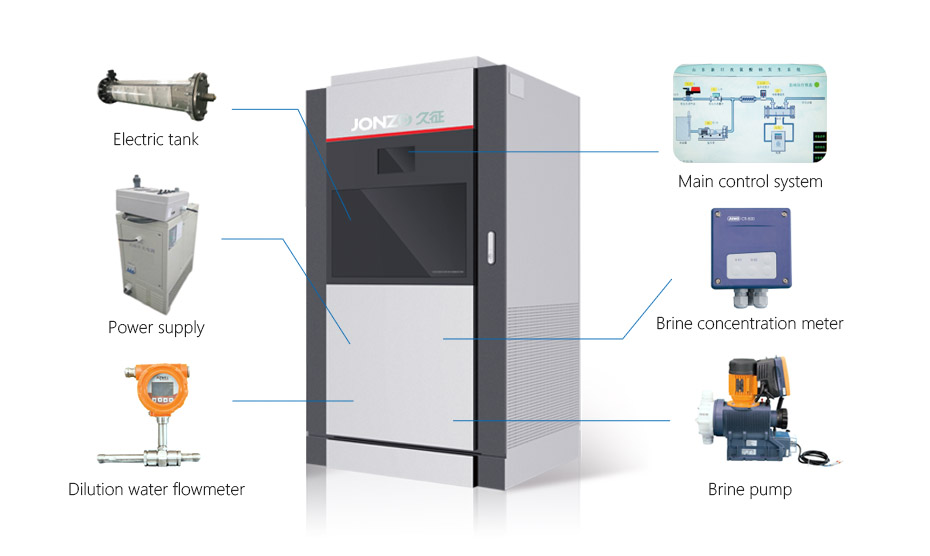

The main unit of generator and the dosing system can becombinedor run independently. The generator can maintain stable dosingsodiumhypochlorite reagent when the generator is malfunctioning ormaintenanceAnd this system can be convenient for users to adjust thenumber of generators.

Based on the technology of ARM series processor, the special controller is developed independently. lt has independentoperational analysis ability to adjust the operating parameters of the equipment intelligently, and to ensure the operation of theequipment in the best working condition with stable and reliable performance.

PID control technology is used in PLC to realize the compound control of feedforward and feedback. The mathematicalmodel is used to optimize controlling of dosing process, which could realize more accurately dosing and less consumption.

●Take the lead in designing and manufacturing generators and developing serialized products using industrial standardization mode.

●The main pipelines and cables are integrated in the host, and the modular arrangement of all parts of the system makes the site installation simple, covers a small area, and has a low failure rate.

●The whole equipment is fully automated and unattended.

●The preparation host and dosing system adopt dual control units, which can operate independently and connect with each other. The dosing system can still maintain normal operation during maintenance of the host, and disinfection and sterilization are not interrupted

●The intelligent equipment management and control software is specially developed for water companies to realize intelligent water services. It can perfectly fit with the intelligent management system of water companies to help users realize the full life cycle management of equipment.

●The software monitors the operation status of equipment in real time, gives early warning/alarm in time, and automatically analyzes and judges the cause of failure.

●Eliminate the hidden dangers of the equipment in the bud, ensure that the equipment is always in the best working condition, and extend the service life of the equipment.